Jan Koster - Interview

When playing drums the placement of your kit means everything. Not having your equipment properly set up and anchored can cause you to become distracted and really affect the outcome of your performance. Having to deal with kick drums and hardware sliding away from you has been a continuous problem even with the advancement of drum rugs. It seems everything with the drums has evolved except what we choose to place them on….carpet.

Carpet can be large and cumbersome which makes it hard to pack and transport. Having to lug around an old smelly rug can be disheartening to say the least, especially when it’s riddled with holes from spikes constantly poking through. Not to mention that having carpet directly underneath your kit will muffle your drums, taking away the full sound potential from the instrument itself. Now drummers have another option that provides stability, good looks, and a consistent set up every time. The product is called Drumplates- developed by long time drummer and production manager Jan Koster.

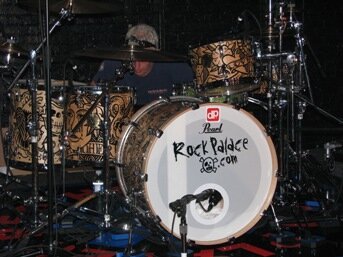

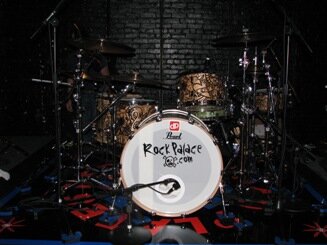

Jan and his team are looking forward to a great response when Drumplates will be displayed at this year’s Winter NAMM Show. I was able to catch up with Jan during the Buddy Rich Memorial Concert, where he was setting up some plates for Chad Smith’s performance on his beautiful custom kit.(pictured below)

Although Chad received a top of the line custom set, there are several other models available, making it affordable for everyone looking for something better than their mother’s throw rug. In the following interview Jan talks to us about how his company started, and what this new sensation is all about.

DC: This started out as a concept of yours that’s been in the works for over 20 years now. Where did you get the idea for the drumplates themselves?

JK: I got the idea when I was a production/tour mgr. and teaching a couple years ago with this band. It was a rather big production with a custom stage and backline design, a very slick production. Then out of the cases came this VERY expensive DW drum kit. On the first day of the tour I saw the drum tech walk up with this smelly piece of carpet that was full of holes, with tape all over it and I just thought “This doesn’t make any sense.” Why would you spend over 100K on designing your stage and then do this? So I felt that somebody had to do something.

DC: Like putting cheap tires on a Lamborghini.

JK: Exactly! We’ve got a Lamborghini but let’s stick some old tires from a VW on there. It just didn’t make any sense. The first thing that came to mind was that somebody had to do something. So I started thinking about it and figured that it was probably going to have to be me. After playing drums for over 20 yrs. there was a couple things it had to do:

- It has to deal with the never ending problem of sliding drums.

- Completely lock the drums.

- Make for a quick and repetitive set up.

- It has to improve the sound and also be quick, light and safe.

In other words I didn’t want to use any metals whatsoever. When you have products out on the road and things get thrown around you can really get some nasty cuts on your hands resulting from dents and nicks in metal. So I started looking at plastics and spent about a year on research and development in 2003. I started learning about plastics and stepped into the world of Velcro and found that there were like 5000 different ones. They come in pairs like wife/husband sort of thing and obviously trying to avoid a metal winch, one night I literally woke up and said “That’s it! I’m working with Velcro, so why not try making a winch of Velcro as well?” So I did and it worked brilliantly, then as the product started to take shape I started looking into patents.

Before you go for a patent they have this new research thing. In other words they will search for anything that is familiar to it or any companies that might object to it. Obviously, I thought there has got to be something out there already, but if there was I would probably already know about it. So after about a year and a half the patent guru came back to me and said there was nothing out there.

DC: So it took the better part of a year to research everything and finally get the patent approved?

JK: Yeah, they research everything for you worldwide and then come back to you with advise like “Don’t go for it because it’s already out there” or “You have a good chance at getting it” and that’s what they said, so we went for it and we got it.

DC: I’ve noticed a lot of inventors are dissuaded by the whole approval process and the time it takes to do the research. Do they usually give you a projection that it’s going to take that long or does it just depend on the nature of the product you’re seeking a patent for?

JK: It’s the nature of the patent as well. On every patent there are categories, some are easier and some countries are quicker than others, but we got it and luckily my father was able to help me out financially because it costs a shitload of money to get it done. It’s insane and it’s really something you don’t want to think about too much about it because it’s basically a little stack of papers that cost about 100K…it’s insane.

DC: WOW! Is that just for them to do the research with no guarantees?

JK: No that’s for actually getting the worldwide patent and everything. Once I got that I had it severely road tested by Caesar Zuiderwijk the drummer of Golden Earring and also Bart Nederhand from Peter Pan Speedrock. Peter Pan is pretty much the Sex Pistols/ Old Guns N’ Roses of the Netherlands, they drink hard and party hard. So I said go with it, spill your beer on it, get em’ dirty, put them out in the rain, REALLY beat this thing up good….I want to know what happens.

DC: So they helped out with some of the R&D for you?

JK: Well they did the road testing for me. They had it out on the road for two months and the drummer Bart made a bet with the crew saying “I don’t think you guys can f%&! this up.” And the crew says “oh, we will….don’t worry.” I think the stake was for a bottle of Jack and after 2 months Bart won the bottle of Jack because it was working great. By then they hadn’t cleaned it or anything so it looked like shit but since it’s plastic all you need is a wet cloth to wipe it down and it’s clean again.

DC: As far as plastic is concerned, did you get that idea from some of the plexiglass shields that have become popular and thought it would work underneath?

JK: No, not really, I’ve never really liked those things. I did think about a surface that had to be hard because sticking a carpet underneath drums is like sticking a towel on your drumhead. It dampens the drums and kills the resonance, so it had to be a hard surface. Because I wanted a product that was light and easy to carry I had to forget about metals and you definitely don’t want to use wood, so it had to be plastic. Now obviously, it couldn’t be plexiglass because it’s too stiff- it doesn’t bend, it breaks and cracks so we had to find a plastic that would have the toughness of plastic but would bend like hard rubber. You can bend them in any shape and they will always return to their original shape.

DC: Not only did you make a product of great quality but you also made it affordable by offering several different series of drumplates. When I met you back stage at the Buddy Rich Memorial you were assembling Chad Smith’s set up which you described as the “Ferrari” of the series. Could you explain to me some of the characteristics of the entry level series that you offer as well?

JK: Sure, basically there are five different kinds of plates.

The Junior Pro Series is 6.5 ft x 3.1 ft and is perfect for smaller kits and starting drummers. It’s made from the same quality materials as the other plates.

Then we have the Junior Pro Series 2 which is 6.5 ft x 5 ft. This is more for the gigging drummer that plays several times a month or for the pro guys with smaller kits as well. They’re also our best seller because these two series basically cover the majority of the masses.

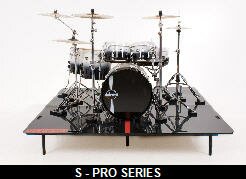

The S Pro Series is 6.5 ft x 6.5 ft which allows for more room. These are for the pro guys and also come with an all weather gig bag w/ shoulder strap. Another advantage to the S Pro Series is the add-on E Plates which are extension plates that can be used widen your set allowing from more room.

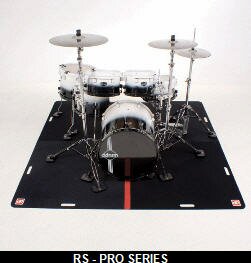

Then within the same series the RS Pro and the “R” stands for RESET. We make the plates the same except that they have Velcro all over the plates for quick changes. We sell those mainly to studios and rental companies, or promoters that use different drum kits on a regular basis. With the Velcro all over the plates the sound reflex isn’t as big, but it’s still there.

The last series is the Custom Pro Series which you had seen that we just did for Chad Smith, Jason Bonham, and we’ll be doing a few more here soon. No deals have been officially closed so I can’t’ tell you who they are yet but we’ve been talking to a couple of really big guys but maybe you’ll see them out on the road here soon. These plates are a 5mm thick opposed to the other series that are only 3mm. The reason for that being is we can do a full color 3-D printing on it, so basically we can put ANY image you want on the plates. Therefore, the plates don’t bend as much so the print doesn’t go all wacky on you. Also you don’t want the Velcro strips connecting the plates so we came up with a click system allowing the plates click into one another keeping the surface completely intact. Those are indeed the “Ferrari’s” for the Chad Smith’s and the people that can afford them.

DC: When I saw the plates you made for Chad I noticed that they were on their own independent riser. Once I researched the website I notice they were elevated off of the ground by support legs.

JK: Right, that was just done for the photo shoot. The plates are flat so you can stick them on the floor, drum riser or wherever you like. They don’t have legs underneath, that was just used to make the plates more visible on the website.

DC: Have you had a fair amount of responses from some of the local and private recording studios? I think this would be an answered prayer for all of the sound engineers out there.

JK: Yes actually, we’ve been selling quite a few to studios here in Holland. We’re starting to sell now to Germany, Belgium, France, and currently several studios in England. That’s definitely going on and the word of mouth has been tremendous. Unfortunately, I can only be in one place at one time. What we are trying to do now is lock in distribution deals for all the various territories.

DC: As far as packing the plates for transport it seems fairly simple being that it has its own carrying case. What is the typical weight for a set of Drumplates?

JK: They Jr. Series is about 19-22lbs. The S Pro is about 45 lbs I believe.

DC: So they’re pretty much lighter than your kick drum?

JK: Oh yeah, they’re really light.

DC: As far as the drum blocks are concerned, those just seem to be mounted by Velcro stickers. Is it easy to remove and replace those once they’re set up?

JK: Definitely, they’re very easy to replace. You stick the Velcro loop pads onto the plates and then stick a block on top of it. The blocks have the Velcro hook underneath so you can take them off easily, grab a spare patch and position it somewhere else and then stick the block back on. On the RS Pro’s you can just take the blocks off and put them anywhere you want right away.

DC: Well, I can see that you definitely did your homework to cover every situation before you came out with this.

JK: I spent a year on it and the juniors come very nicely packaged in a sturdy carton box that you could even use to transport it if you wanted to. This winter we’ll have a nice affordable gig bag for the Junior 2 Series for all the giggling drummers.

DC: What is some advice that you could give to all of the entrepreneurs out there looking to invent and market their own product.

JK: if you think you have a really good idea don’t rush into anything and really take the time to look at it from all sides and perspectives. Give it some good thought, and talk to people you obviously trust and have them shoot at it and after week or so if you still feel that you’re right and you should do this, then you should go ahead full blast and do it. And don’t let anyone else tell you otherwise. You have to set your own standards-one of the things I’ve done since day one is really look at “quality” right away. I think quality prevails always but it’s also a combination of things:

- The product has to be good

- It has to be reliable

- The name has to be right

- Your company has to make a statement that makes sense.

These are some things we considered and I think we managed to achieve this.

DC: It looks as if it packs up and transports very easily.

JK: It’s light, quick, and fast. You take the drums off, remove the red hook, the plates fold in and you stuck them in your carbon box or gig bag. The main three things of the system are:

1. Your drums are completely locked

2. It makes for a very quick and repetitive set up EVERY TIME.

3. It enhances the sound of the drum BIG TIME: Way more bottom end and overall clarity because the drums resonate making them more dynamic.

Another thing is that they’re very light making them easy to transport. What’s really interesting to me –and I must admit I hadn’t thought about is getting responses from the drummers saying they are better players now because they don’t have to worry about their drums sliding anymore. You know how it is- you’re playing and you start to feel something sliding and once that happens you lose concentration.

DC: Are there any problems that you encounter with using these with drum racks?

JK: I’m not much of a rack man; I think I’m too old for that. I’m hoping to see a major change for the drumming community because if you have plates then you don’t need to have really heavy hardware with spikes digging into everything. Drum companies are making their hardware heaver and heaver with nastier and bigger spikes every day. I’d like to work together with a drum manufacturer and try to persuade them to make light affordable hardware with their kits. The larger the spikes , the faster it’s going to eat through your carpet, it’s as simple as that I’m talking to drum techs and everybody is bitching and complaining cause it’s getting ridiculous. People are breaking their backs carrying all this stuff around.

DC: And I’m sure it cleans up easily instead of lagging around some smelly old rug everywhere you go.

JK: It’s been treated to be UV and weather proof so all you need is a wet cloth.

DC: Could you also use the plates for percussion instruments such as marimbas and xylophones which are normally on rugs?

JK: We actually have been selling quite a few to percussion guys and they seem to love it due to the difference it makes, there’s really no end to this. I’ve also registered to Classic Plates which we will be doing for orchestras. We’ll be making smaller plates for cello’s and such so I’m not done yet. Being a drummer and having a production background I get a good vibe of what people like to work with and I take pride in that we make all of our products ourselves.

DC: Today it seems like there are so many gadgets and gizmos being thrown together just to sell something as a fad. Drumplates seems like you took the time to study and research it and you’ve been able to make a great product that’s very practical and affordable.

JK: The only problem is that they last. I won’t be selling you new plates every year but it doesn’t matter. I’d rather have a good product out there that lasts and people enjoy working with than just making a quick buck.

DC: Do you have any upcoming promotions, contests or specials for Drumplates as of right now?

JK: One of the ideas is in 2010 is to have a “Carpet Burn” outside of the NAMM show. I want to turn it into an annual event: bring your carpet to burn and get 15% off. I’ll call it The DP Annual Carpet Burn.

DC: Good luck getting the city to approve that one, they won’t even let you smoke outside in certain places. But if you do, I’ll send you mine!

For other accessories and models such as the Roland V Drum Blocks

visit the Drumplates website by clicking HERE!

source: drumplates.com

Drum Lessons | Drum Solos | Drum Events | Drum Transcriptions | Drum Tuning | Drumless Tracks | Reading Music | Drum Rudiments | Drumkit Dynamics | Drum Tricks

Drum Fills | Drum Kit Tours | Drummer Interviews | Drum Odd Time Signatures | Drum Grooves | Drum Exercises | Drum Hardware | Drummer Jobs | Billy Ashbaugh | Chad Sexton

JoJo Mayer | Gavin Harrison | Stanton Moore | Ray Luzier | Artimus Pyle | Morgan Rose | Benny Greb | Todd Sucherman | Robert Sweet | John Blackwell | Jeff Ocheltree

Drums: Crush Drums | Cyclone Drums | Dixon Drums | DW Drums | Gretsch Drums | Pearl Drums | Tama Drums | Sonor Drums

Cymbals: Amedia Cymbals | Istanbul Cymbals | Meinl Cymbals | Paiste Cymbals | Sabian Cymbals | Zildjian Cymbals

Drum Sticks: Pro-Mark Drumsticks | Vater Drumsticks | Vic Firth Drumsticks | Zildjian Drumsticks | 3 Drumsticks

YouTube Videos

YouTube Videos

DC Comments (

DC Comments (

Interview Information

Interview Information Related Photos

Related Photos Other Interviews

Other Interviews

Your Opinion Counts!! Please Leave a Comment!

Earn Diddles / Points for Drummer Merchandise.

20 Diddles per comment earns you savings on DrummerConnection Merchandise!

Login or Register (see below) and start Diddling!